DDS SMART EFFICIENCY SYSTEM

HOW IT WORKS

KEY PRODUCT FEATURES

ALL-IN-ONE OEE SYSTEM

Save time and money with a cost effective full complete system to improve overall equipment effectiveness. Fast to implement. No extra hardware, software or IT visits needed.

IoT ETHERNET SYSTEM

Strong ethernet connection to local network allows multiple users to access real time and historic data remotely for better collaborations.

ADD MULTIPLE DEVICES

Add up to tens or hundreds of devices on the same ethernet or WIFI network at one location, View all displays from one main screen.

AUTOMATIC DATA COLLECTION

In addition to manual data recording, automatically collect data with a range of sensors available to free up valuable man hours.

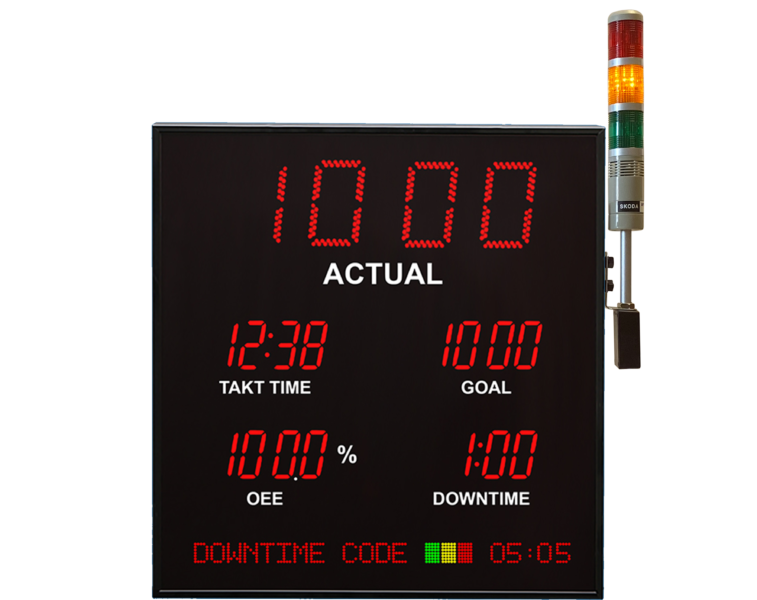

INSTANT AUDIOVISUAL ALERTS

Add piezo buzzer alarms, Bells, or Andon light towers based on your needs to provide instant feedback and alerts.

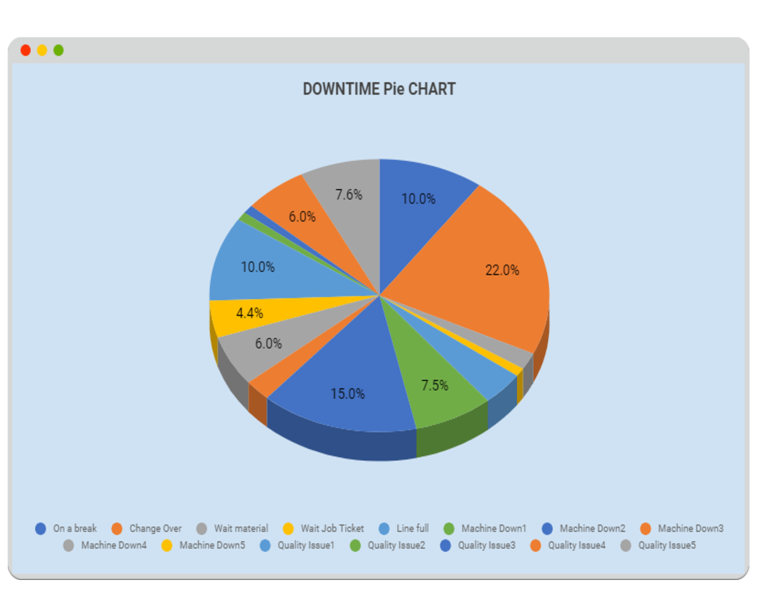

DOWNTIME TRACKER

Track downtime and collect data with user defined custom downtime reasons. Historic data can be exported into excel for easy analysis.

EMAIL NOTIFICATIONS

Setup custom rules for tier-based email notifications. Choose who and when alerts should be sent.

AUGMENT MACHINERY

Completely replace or add as a compliment to existing OEE system and machines

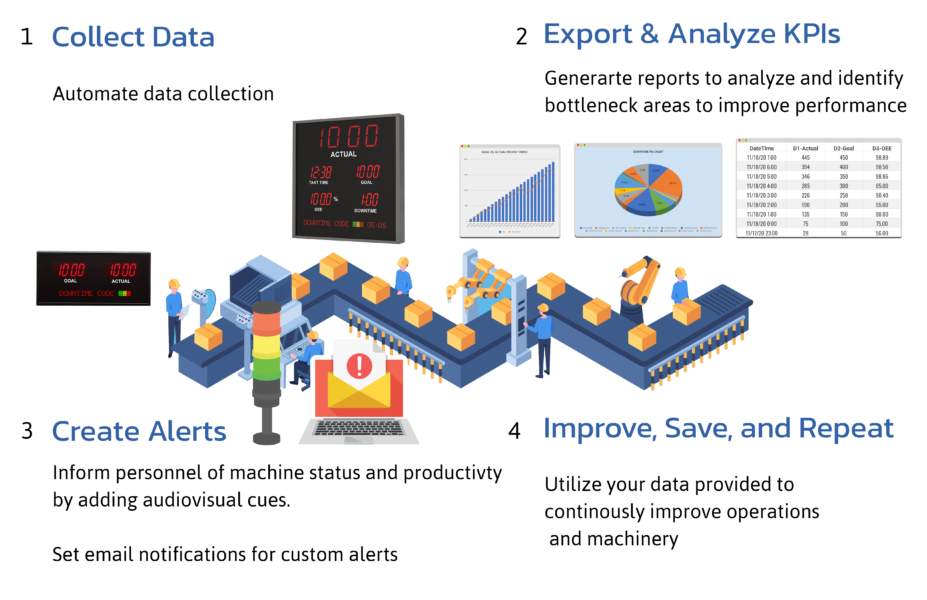

automated data collection

How do you want to collect your data?

Collect data manually or automatically with the help of manual switchboxes, and a wide range of sensors. Our devices can also be connected to existing PLC machines.

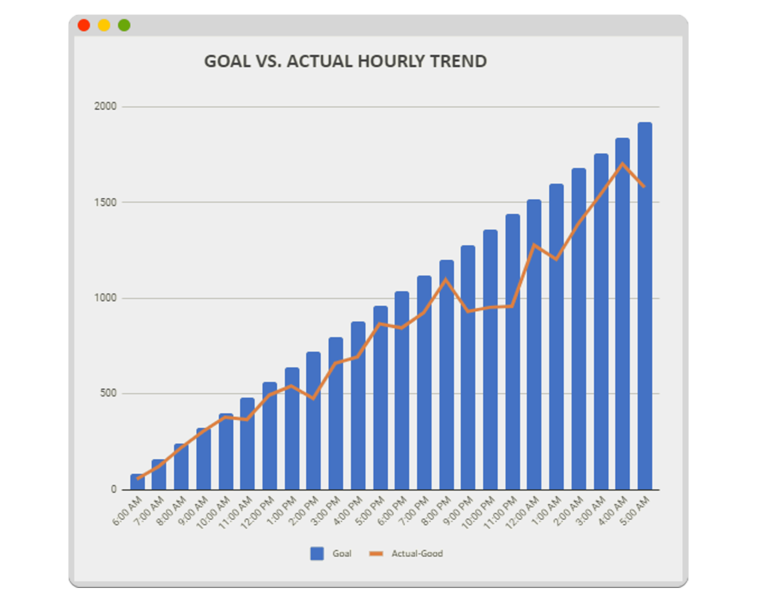

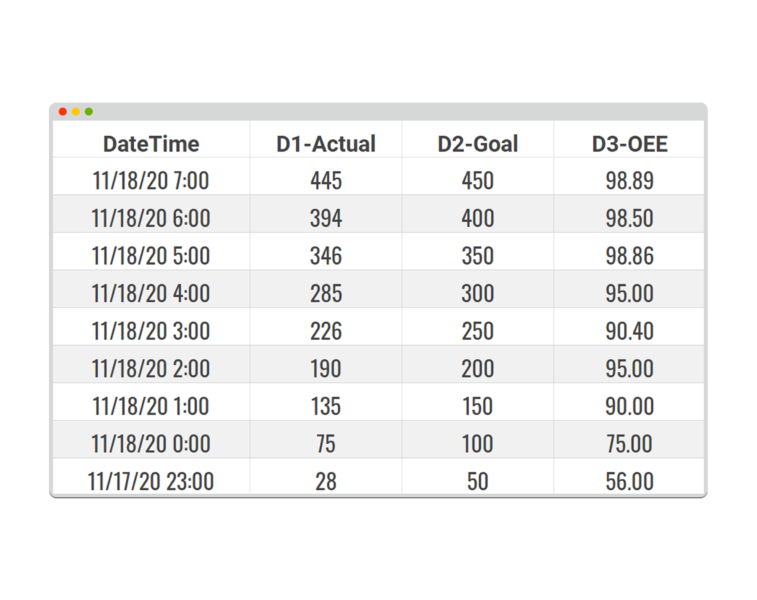

analyze and identify bottleneck areas

Need help analyzing the data? Digital Display Systems offers lifetime customer support and premade templates.

Download up to 6 months of recorded data or approximately 40,000 lines on Excel. Generate reports to analyze and identify bottleneck areas to improve overall performance.

increase employee engagement

If a target is not being met, or if there are any issues causing downtime, instantaneously notify the entire production floor with any of the following audiovisual add-ons: flashing border lights, process timer Andon lights, external alarm bells, or internal Piezzo buzzer alarms.

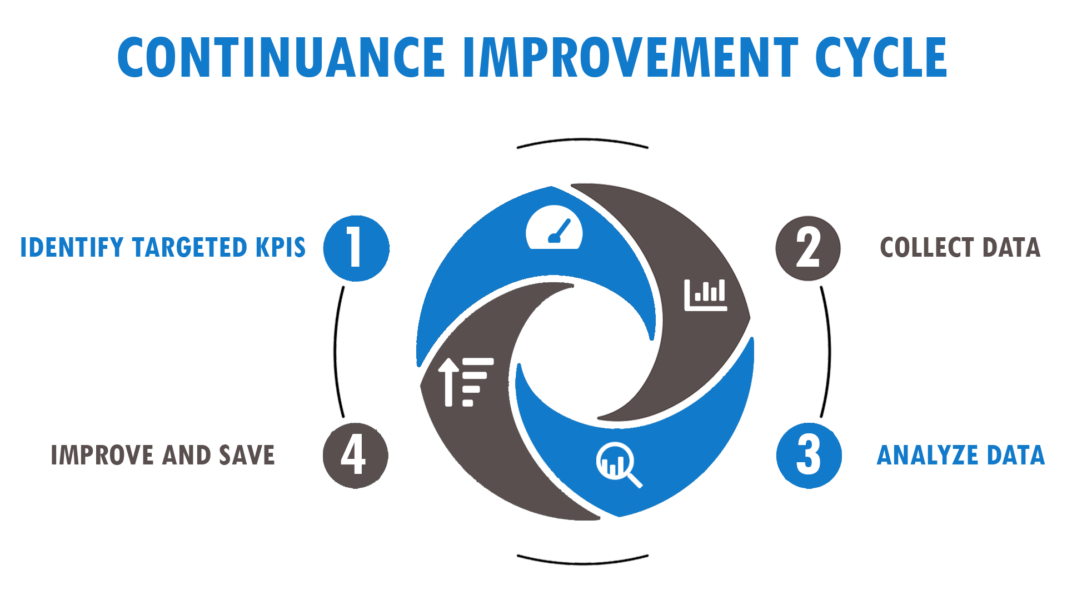

IMPROVE AND SAVE

Use data provided to continuously improve operations and machinery.

SMART EFFICIENCY SYSTEM PACKAGES

THREE DISPLAY SYSTEM

Starting at $1,799

FIVE DISPLAY SYSTEM

Starting at $2,499

SIX DISPLAY SYSTEM

Starting at $2,999

BENEFITS

REDUCE

Downtime

Operation Costs

Production Waste

Production Rejects

IMPROVE

Production Throughput

Overall Equipment Effectiveness

Machine Availability

Production Quality