Most manufacturers today are still inputting data manually. Collecting data manually is very time consuming and is not as efficient as automated data collection. Collecting data manually puts you at risk of not having precise data due to the factor of human error.

In the manufacturing industry precise data is very important in identifying KPIs and bottleneck areas. If you do not have precise data you will not know which areas in your operations are struggling.

Another disadvantage of collecting data manually is that it prevents your employee from contributing to the throughput of the operations.

Automating data collection frees up your employee’s time so they can get back to their day to day operations. This enables your employee to contribute to help improve the overall throughput of the operations. By automating data collection you can feel ensured that the data you are collecting is precise. This then allows management to focus on areas of improvement which will then help improve the OEE.

How can Digital Display Systems help you on your digital journey?

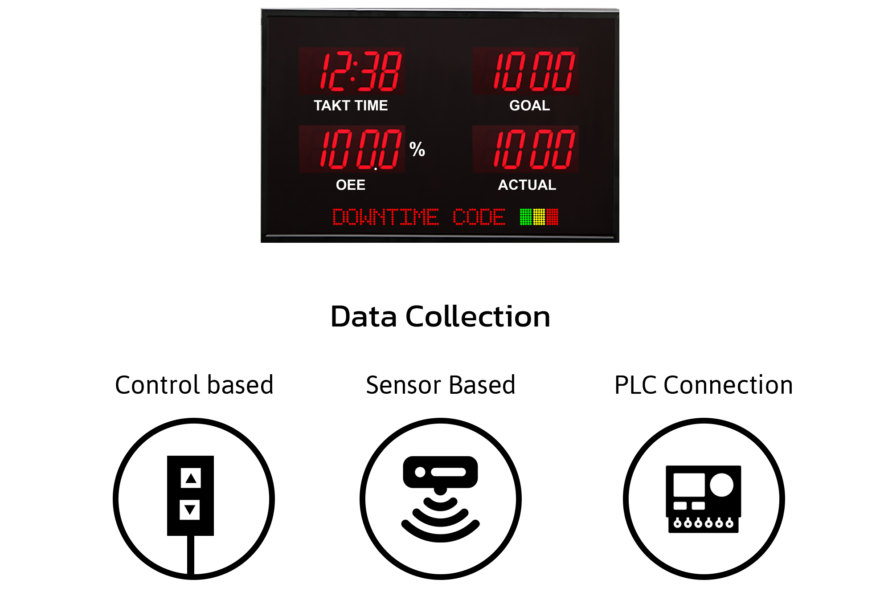

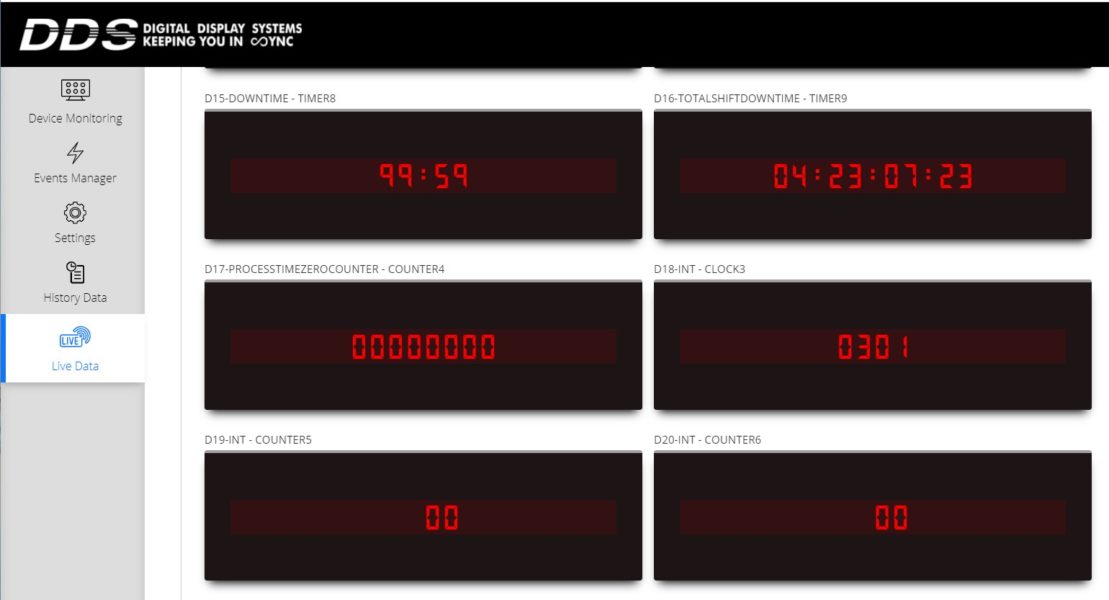

With our newest Smart Efficiency System operations can automate their data collection by utilizing a range of sensors. From the sensors you can choose what data you want to share to the floor on our large LED scoreboard displays.

The scoreboard also collects data behind the scenes for management to view / download on our intuitive online interface (No additional software is needed).

Automating your data collection is just one of our groundbreaking features that can help your operations maximize its throughput.

To learn more about our products full capabilities click the button below

LEARN MORE